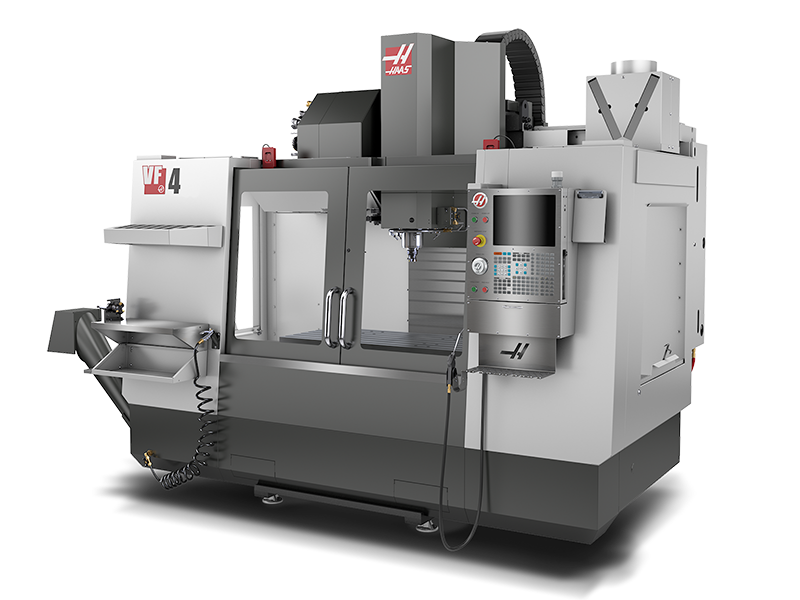

A pilot operated fitting on Haas VF4 is one of the most important fittings in optimizing hydraulic systems for your CNC machine. Proper installation of a fitting will ensure better machine performance, smooth operation, and fewer problems at the maintenance shop. Here, we are guiding you on how to install a pilot operated fitting on Haas VF4, tips, and common mistakes that may happen.

What is a Pilot Operated Fitting?

Pilot Operated Fitting in Haas VF4 machine is a hydraulic control valve that helps in managing hydraulic pressure and fluid flow throughout the machine system. It is a controlling fluid movement so that every part of the machine can experience an appropriate amount of force applied at the most proper times. It further resulted in the operation of more parts with high precision and performance.

Why the Pilot Operated Fitting is Important?

The Pilot Operated Fitting of the Haas VF4 does the most important duty in pressure regulation through hydraulic pressure, which is required for machine performance. The correct fitting installation allows the system to be under minimum failure and ensures performance inside the range. Incorrect installation can lead to leaks, erratic pressure, and full failure of the hydraulic system.

Knowledge of parts of a Pilot Operated Fitting

Knowledge of the parts of the Pilot Operated Fitting of Haas VF4 goes like this in practice. The parts are;

- Valve: it controls the movement of fluid.

- Spring: it allows the pressure where necessary.

- Pilot Signal: it is the auxiliary signal that activates the valve.

Each of them complements each other in controlling fluid efficiently.

Preparedness before Installation

Before you start the installation, make sure that all your tools and parts are pre-prepared. These will include your Pilot Operated Fitting, wrench set, thread-sealing compound, and clean cloth. Make sure that it is the correct fitting for your Haas VF4 model so you will not have any compatibility trouble.

Step-by-Step Installation Guide of the Pilot Operated Fitting

1. Switch Off the Power Source of the Machine

You need to cut off the power supply and disconnect the machine from the electricity before you can begin your work on installing it.

2. Removal of Old Fitting

Remove the old fitting with appropriate tools, be gentle to avoid damaging anything, and take note of what has been done so that it also goes well when installing a new one.

3. Cleaning Fitting Area

Clean the installation area so there will be no debris, dirt, or any residue of hydraulic fluid. That way, there won’t be any leaking with the new fitting that is going to be installed.

4. Thread Sealing Compound

The sealing compound applied on the threads of the Pilot Operated Fitting on Haas VF4 is of excellent quality sealing. No leakage; it is firmly held in place to prevent any sort of fluid leakage.

5. Installation of the New Fitting

Tightening it up, not overtightening because of the chance of ruining the thread while doing it, and let it snug but tight

6. Reconnection Hydraulic Lines

Reconnect hydraulic lines to the fitting and tighten connections. One should take proper care before reconnecting as damage or damage to hydraulic hoses can be visually determined.

7. Testing of System

The machine is turned on once all connections are in place. The system is tested for leaks or anything odd. Once everything functions normally, then the installation is considered complete.

Errors during Installation

- Over-tightening: While a fitting is over-tightened, it damages the thread and thus causes leakage or failure.

- Sealing Compound Not Applied: When the thread sealant is not applied, then fluid leakages take place that reduces the system’s efficiency.

- Use the Wrong Parts: Using the wrong fitting may cause damage to the efficiency of a system. Part numbers and specifications must always be confirmed before being installed.

Inspection for Leaks After Installation

After every installation of the Pilot Operated Fitting on Haas VF4, check its fittings for leakages. The first sign of an inoperative device is leakage of hydraulic fluid around the fitting. If there is leakage in the fitting, then it should be tightened or reapplied with the sealing compound.

Routine Maintenance

Regular maintenance is required to extend the life of your Pilot Operated Fitting on Haas VF4. Check fittings for leaks and signs of wear and tear and clean them periodically to ensure hydraulic performance.

Troubleshooting Common Problems

If your system fails to work, some of the most common problems along with solutions to troubleshoot them are as follows:

- Leaks: Just tighten up the fitting or reapply the sealing compound.

- Low and Too Much Hydraulic Pressure Problems: In this, the pressure remains either too low or too much; thus, the fitting gets filled or some so do some errors exist in the hydraulic lines.

- There’s No Response: For checking the control signal alter for an existing issue, it can also be an electrical contact that is causing some issues

What Happens When You Must Change the Pilot Operated Fitting

Even if well taken care of, fittings have their lifespan. The following are some signs that the pilot-operated fitting on Haas VF4 may be due for replacement;

Visual damage on the fitting or threads.

The leak continues to leak even after tightening and sealing.

Weak hydraulic pressure as well as machine performance

Tips to Lengthen the Service Life of Your Pilot Operated Fitting

Extend the life of your fitting with these simple tips:

Check the fitting from time to time for wear, cracks, or leakages

Dirt and debris damage. Clean the area of installation

Use quality parts: Use only high-quality compatible fittings for your Haas VF4.

Role of Professional Help

While it is something that you do yourself in installing a Pilot Operated Fitting on the Haas VF4, if you are not sure about anything, call up a professional to do this for you. A specialist technician can do the whole installation properly and can solve any problems that may occur.

Hydraulic System Safety

Hydraulic systems are dangerous at high pressure. One should always employ protective gear when working on hydraulic fittings. One must be sure what he is doing before he undertakes any type of maintenance or installation.

Benefits of Proper Installation and Maintenance

An appropriately installed and serviced Pilot Operated Fitting on Haas VF4 promotes smooth running, efficient performance, and failure in the system. It thus avoids too much downtime or repair cost and helps prolong your machine’s life.

Conclusion

This Pilot Operated Fitting, for Haas VF4, will keep your machine in its best condition by keeping it properly installed and maintained. It guides the fitting to proper installation and will last for and serve you well for a good number of years. The preventive maintenance and inspections of these will ward off problems and extend your machine’s life, giving you the best performance that this machine can offer.